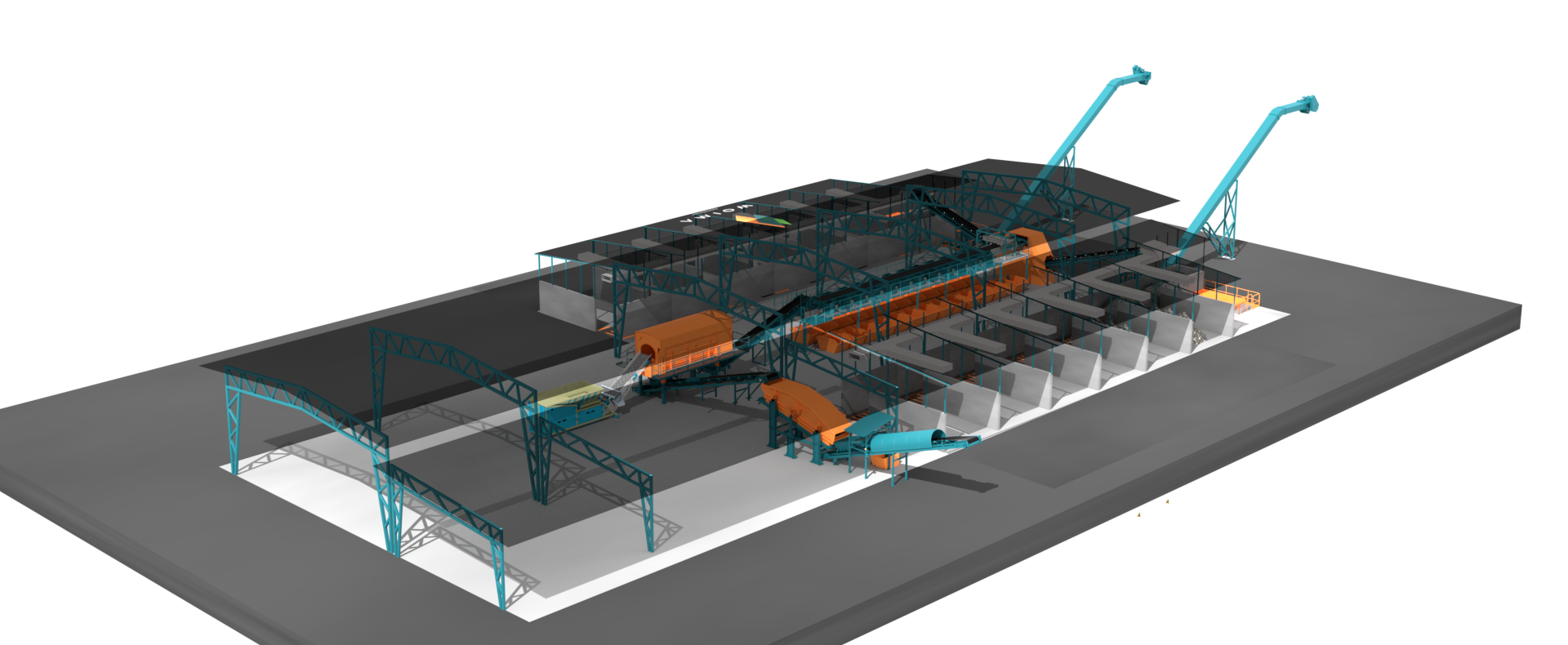

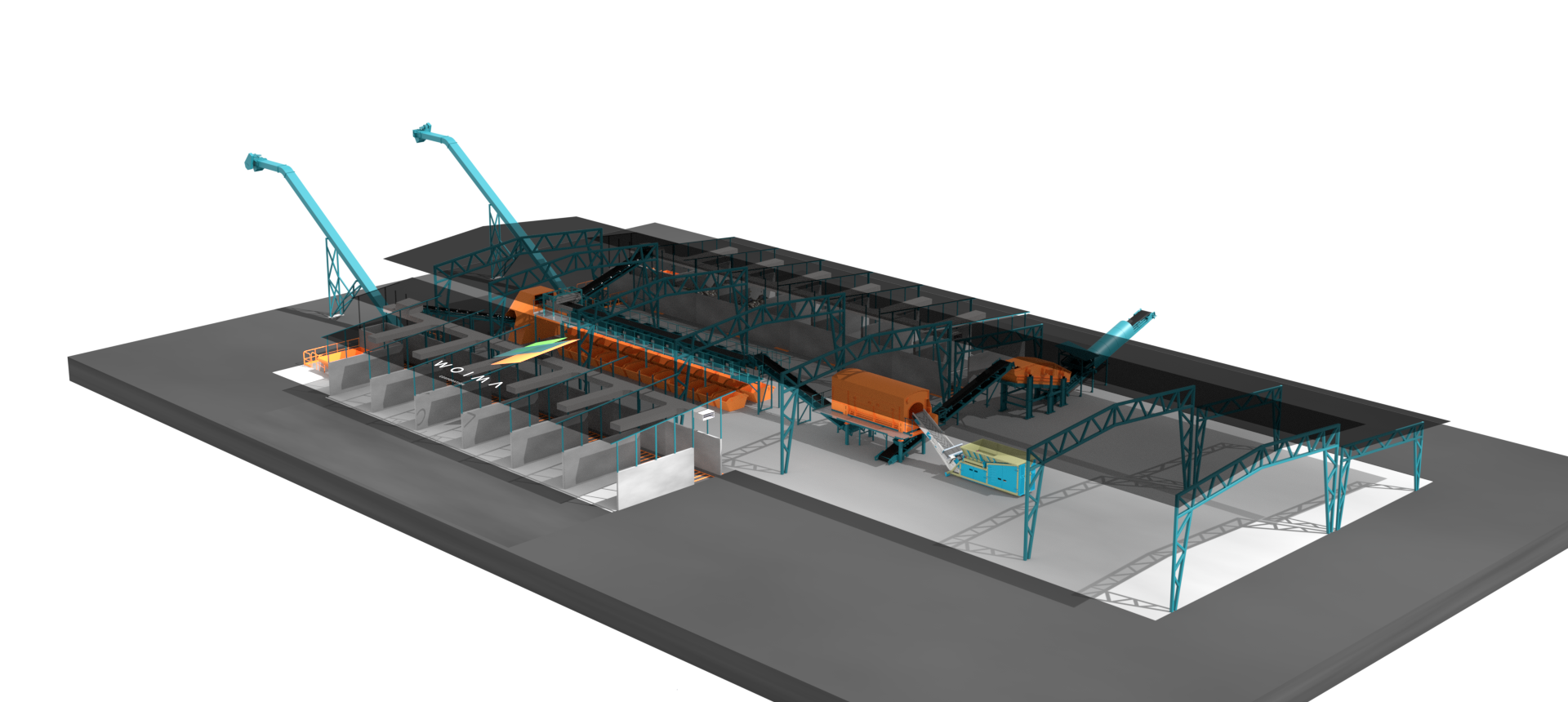

Waste pre-sorting

The waste pre-sorting process starts with weighing the incoming garbage trucks before depositing their waste in the tipping storage. This acts as a buffer and enables deliveries 24/7 independent of the pre-sorting plant operating hours. It also ensures continuous waste flow during the pre-sorting operation.

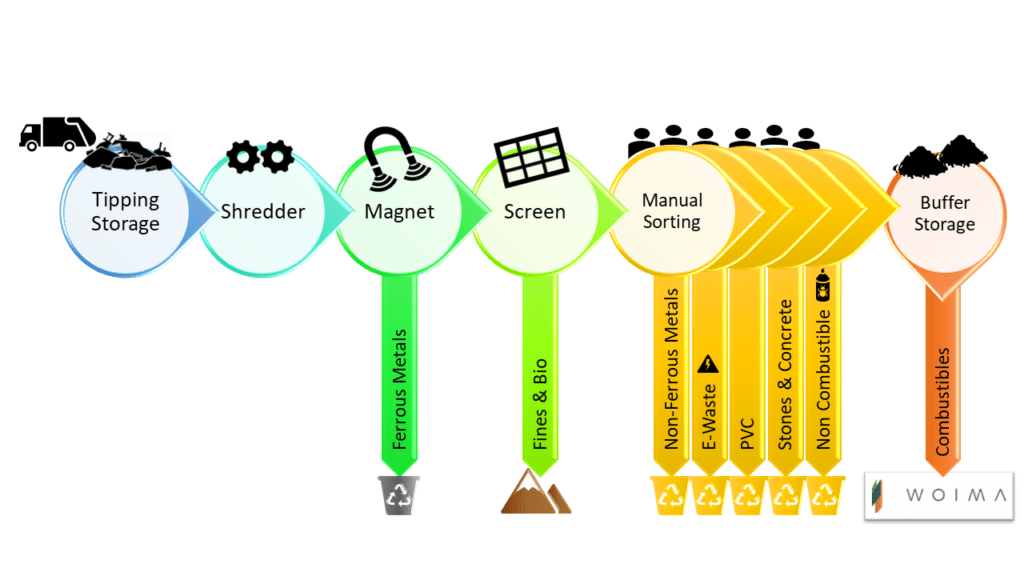

Next step is feeding the waste into a shredder opening the bags and crushing the large objects. Crushed waste runs on a conveyor belt, where a magnet removes the ferrous metals, onto a screen that will separate small particles, like biowaste, sand, soil and ashes that are hard to pick by hand. Biowaste can be used in biogas generation or composted, while the rest is recycled or landfilled.

The main waste stream from the screen is evenly distributed on a conveyor belt and passes through a manual sorting station. During manual sorting all inert and harmful material, such as metals, glass, electronic waste, PVC etc. is removed and recycled as raw material. The combustible waste fuel continues into a buffer storage. At this stage the waste is mainly composed of wood, plastics, textiles and some residual waste matter. The purpose of the buffer storage is to ensure that the waste-to-energy plant will have a continuous supply of fuel. The buffer is dimensioned to cover those periods, when the pre-sorting plant is not operating, such as weekends and holidays.

The waste fuel is then fed to the wasteWOIMA® incineration plant. Exactly the right amount of fuel is conveyed to the combustion grate depending on the fuel calorific value and moisture. This way complete combustion and maximum extraction of energy is guaranteed.